High strength 8 strand PP Polyester Nylon mooring rope used for marine

The most common materials used for fiber mooring lines are polyester, polyamide, polypropylene and polyethylene. Some ropes are made of combinations of these materials.

1. Beautiful colors and wide application 2. High resistance to weather

3. High corrosion resistance 4. Good wear-resistance

5. Easy operation

|

Material

|

Polypropylene

|

|

Brand

|

Florescence

|

|

Diameter

|

20mm-160mm or as your request

|

|

Type

|

Braided

|

|

Structure

|

8 strand braided

|

|

Color

|

White as your demand

|

|

Place of origin

|

China

|

|

Packing

|

Coil,roll inside + woven bag or carton outside

|

|

Payment

|

T/T, L/C,West union

|

|

Delivery time

|

7-20 days after receive your payment

|

High strength 8 strand PP Polyester Nylon mooring rope used for marine

We are a professional marine ropes supplier in China with 10 years experience, and we can supply you with various ropes such as PP/PE/Polyester/Nylon/Sisal/UHMWPE ropes/Kevlar rope and so on with competitive price. Our ropes have many advantages as follow:

1.PP, PE,Nylon, Polyester, Uhmwpe, Kevlar material ropes can be available;

2.The diameter 4mm~160mm or as your demand;

3.High Corrosion resistance and quality;

4.Various color and widely application;

5.High breaking strength;

If any ropes meet your requirement, please feel free to contact me.I will support you with more our ropes information.

1. Packing–coil/reel/bundle/spool/hank with inner packing,pp woven bags, cartons with outer packing or as requested

2. Product–the type,structure,color and packing can be customized as requested.

3. Sample–free sample within 5 working days,but we’re afraid that you have to pay for the freight charge.

4. Shipping–we will arrange for shipping as quick as 7-20 days after the order is placed.

Our Company Overview

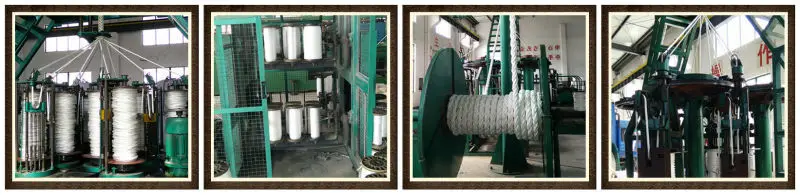

Working flow

We will offer quotation against receipt of customer detailed specification,such as material,size,color,design,quantity etc.

Customer inquiry→Supplier quote→Customer accept quotation→Customer confirm details→Customer send PO to supplier for sampling→Supplier send sales contract to customer→customer pay sampling charge→Supplier start sampling→Sample ready and sent

Sample approved→Customer send PO→Supplier send sales contract→PO&sales contract approved by both side→Customer pay 30% deposit→Supplier start mass production→Goods ready for shipment →Customer settle balance→Supplier arrange shipment→Order finished→Customer give comments after receiving goods